Commercial Sewage Treatment Plants

Tricel Maxus Combi

- Available for projects > 50PE

- All in One tank

- Easy to install

- Reliable and efficient SAF technology

- Low running costs

- Suitable for seasonal loads

Why choose Tricel’s Maxus Commercial Sewage Treatment Plants?

The Tricel Maxus, is a commercial Sewage treatment plant that uses Submerged Aerated Filter (SAF) technology. These highly versatile systems are individually sized to suit every scenario over 50 Population and up to 200 Population requirements.

Tricel Maxus commercial sewage treatment plants are strong and easy to install, with numerous possible configurations to suit any site either 95% final effluent discharge or 98% discharge effluent.

The Tricel Maxus sewage treatment plants are simple in operation and easy to maintain over the product’s lifespan. All electrical components of the plant are connected through the E-III control panel.

Typical installation usages include:

- Multiple Housing Developments

- Hotels

- Restaurants

- Camping / Glamping Sites.

- Factories or Commercial Premises

Free Site Visits in Northern Ireland

Offering you the best value for money wastewater treatment systems in Northern Ireland

Fully Certified Engineers

Depawater's engineers are accredited by British Water, all our products are CE certified

Reliable & Efficient

We deliver on reliability and efficiency in both service and products

How does the Maxus Combi Commercial Wastewater Treatment Plants work?

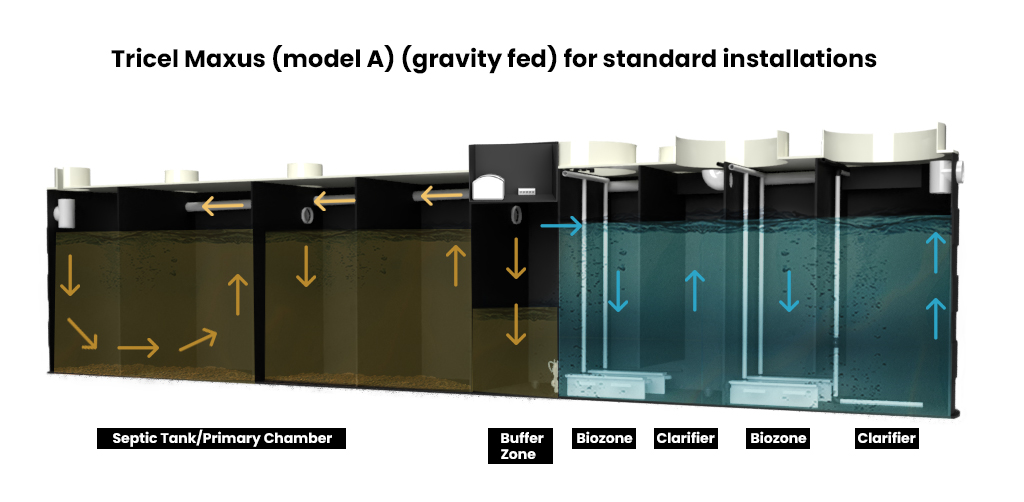

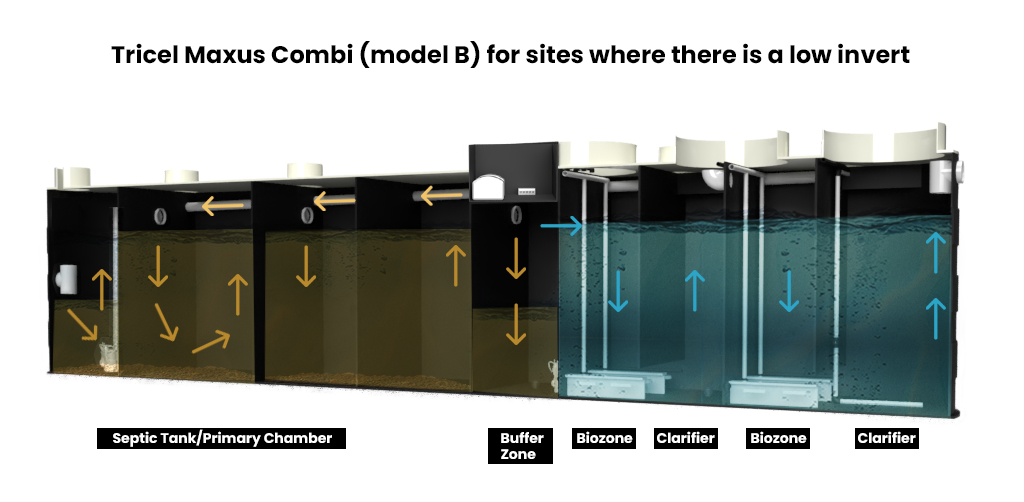

One single tank, 2 models (1 gravity fed and 1 with a pump for low invert).

Tricel Maxus uses SAF technology. This technology treats wastewater through a four-stage process.

Stage 1: The settlement tank (septic tank/primary chamber)

The primary treatment occurs here. As the wastewater enters the Tricel Maxus system, the heavy solids are separated out and settle (forming a sludge on the tank’s base). Subsequently, the lighter solids, such as oils, fats or grease, float to the top of the wastewater and are retained within the settlement tank.

Stage 2: The buffer tank (buffer zone)

The incoming water load fluctuations are evened out here. The wastewater is fed forward into the treatment plant thanks to pumps located at the bottom of the buffer tank.

Stage 3: The biological treatment zone (Biozone)

The wastewater passes through, the submerged aerated filter (with a large surface area for the microbes) and is exposed to aeration.

The aeration is matched to the incoming flow to ensure efficient operation, thanks to the adjustments made by the control panel. Because of this, the system will not clog nor need any maintenance or chemicals.

Stage 4: The clarifier

Here, the bio sludge from the treatment process settles out of the treated liquid. Thanks to the airlift pumps, the bio sludge from the tank’s base is recirculated back to the settlement tank. The fully treated liquid is now ready to discharge from the plant.

Not sure if this product is for you?

We can help you. The only thing you need to do is book a site visit, and we will be able to analyse your ground and guide you towards which wastewater treatment solution best fits your site and your needs.

Work with us on your project

If you are building or renovating a house and require a sewage treatment system installed or a septic tank upgraded, contact us today and speak to our experts to learn which product is best for your needs.