The Tricel Maxus Combi is a robust and efficient commercial sewage treatment solution, designed using advanced Submerged Aerated Filter (SAF) technology. Ideal for applications over 50 to 200 population equivalents (PE), each system is tailored to meet the specific needs of your site.

Engineered for strength, ease of installation, and long-term reliability, the Maxus offers flexible configuration options with treatment efficiencies of up to 98% final effluent quality. All electrical components are managed via the intuitive E-III control panel, ensuring simple and effective operation and maintenance.

Common Applications Include:

Depawater's engineers are accredited by British Water, all our products are CE certified

We deliver on reliability and efficiency in both service and products

Over fifteen years of experience providing an industry-leading professional service

Offering you the best value for money wastewater treatment systems in Northern Ireland

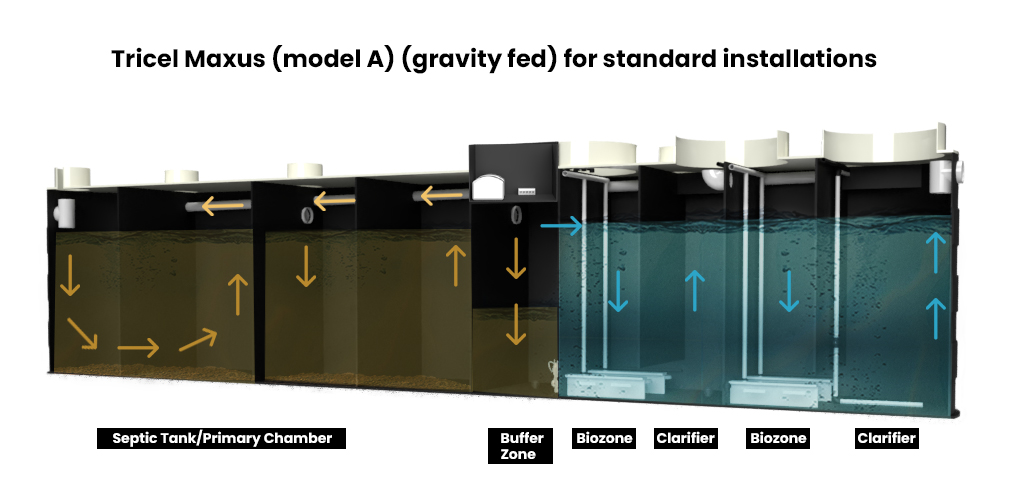

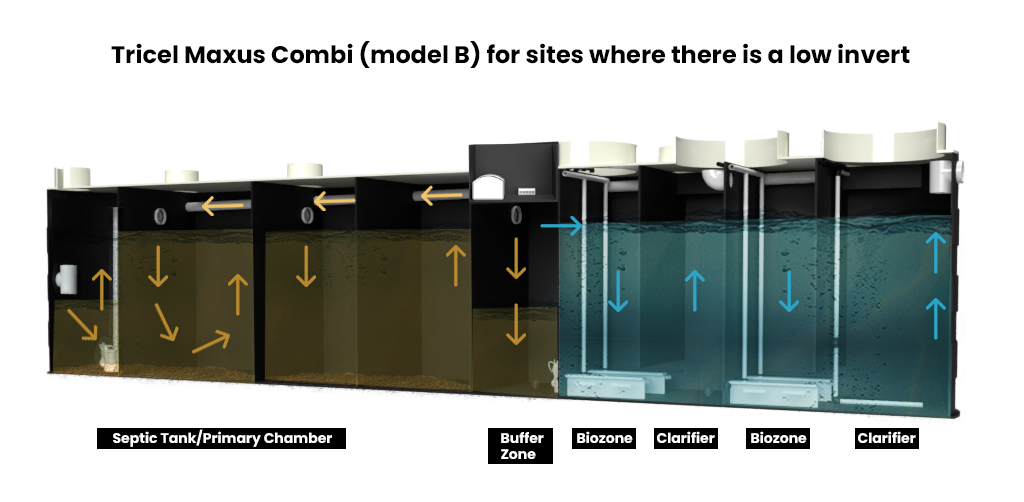

One single tank, 2 models (1 gravity fed and 1 with a pump for low invert).

Tricel Maxus uses SAF technology. This technology treats wastewater through a four-stage process.

Stage 1: The settlement tank (septic tank/primary chamber)

The primary treatment occurs here. As the wastewater enters the Tricel Maxus system, the heavy solids are separated out and settle (forming a sludge on the tank’s base). Subsequently, the lighter solids, such as oils, fats or grease, float to the top of the wastewater and are retained within the settlement tank.

Stage 2: The buffer tank (buffer zone)

The incoming water load fluctuations are evened out here. The wastewater is fed forward into the treatment plant thanks to pumps located at the bottom of the buffer tank.

Stage 3: The biological treatment zone (Biozone)

The wastewater passes through, the submerged aerated filter (with a large surface area for the microbes) and is exposed to aeration.

The aeration is matched to the incoming flow to ensure efficient operation, thanks to the adjustments made by the control panel. Because of this, the system will not clog nor need any maintenance or chemicals.

Stage 4: The Clarifier

Here, the bio sludge from the treatment process settles out of the treated liquid. Thanks to the airlift pumps, the bio sludge from the tank’s base is recirculated back to the settlement tank. The fully treated liquid is now ready to discharge from the plant.

Whether your building a new home or have a commercial project or are upgrading an old system, Depawater is here to help. With over 25+ years of experience, trusted Tricel products, and a personal, professional approach – we’re the team you can rely on to get the job done right. We manage insurance claims, making the process as smooth and stress-free as possible.